Un robot aspirador, también conocido como máquina de limpieza automática, aspiradora inteligente o aspiradora robótica, es un tipo de electrodoméstico inteligente. Utiliza tecnología de inteligencia artificial para completar automáticamente las tareas de limpieza del suelo en interiores. Los robots aspiradores suelen limpiar cepillando y aspirando, aspirando los residuos del suelo en un cubo de basura incorporado para lograr la limpieza del suelo. Debido a su facilidad de manejo y comodidad, los robots aspiradores se han hecho muy populares y son electrodomésticos inteligentes de uso común en los hogares y oficinas modernos.

Requisitos de apariencia de la pieza y análisis estructural

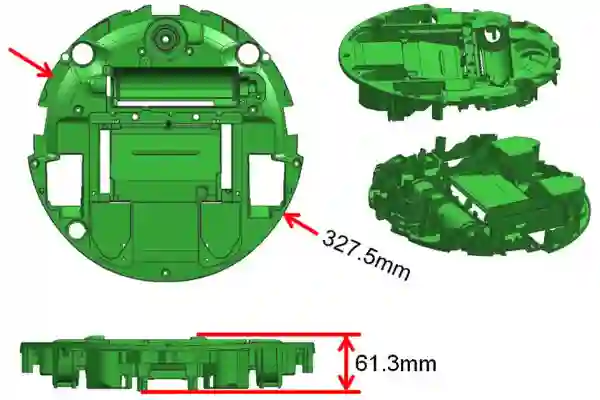

La siguiente figura muestra el dibujo de la pieza de la cubierta del pie de un robot aspirador de una marca de renombre. El material es ABS, clasificado como componente cosmético. Dimensiones de la pieza: Ø327,5 × 61,3 mm. Las características principales son:

- Requisitos de aspecto: La superficie cosmética debe estar libre de defectos como manchas, marcas de hundimiento, líneas de soldadura y rebabas.

- Diseño con socavado: Existe un destalonado en el lado interior de la pieza, lo que requiere un mecanismo de elevación deslizante o en ángulo.

- Complejidad estructural: La pieza grande contiene múltiples cierres, agujeros de pasador y nervaduras, lo que requiere un amplio uso de insertos en el núcleo/cavidad.

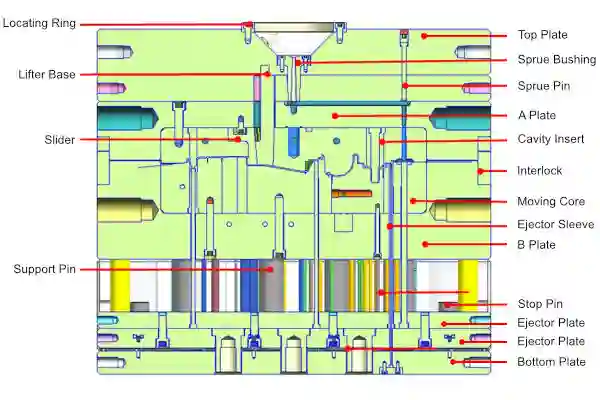

Diseño del sistema de compuertas

- Disposición: Disposición de cavidades 1×1 con un sistema de compuertas secundarias de cuatro puntos.

- Detalles de la compuerta: Tres compuertas realizan la transición de subcompuertas a compuertas principales (comúnmente denominada "conversión de subcompuerta a compuerta principal"), mientras que una compuerta se coloca directamente en la superficie exterior de la pieza. Las compuertas están situadas en la línea de separación y en las superficies de cierre para garantizar un llenado equilibrado.

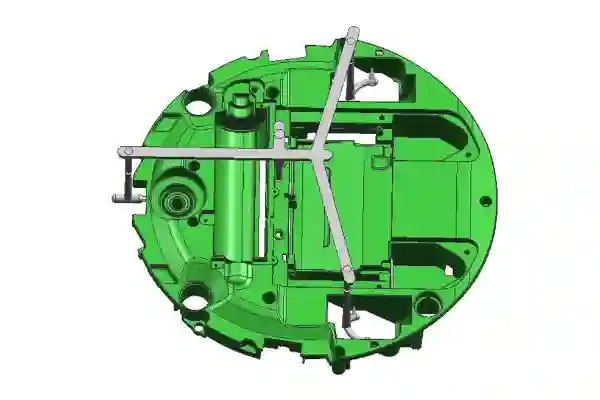

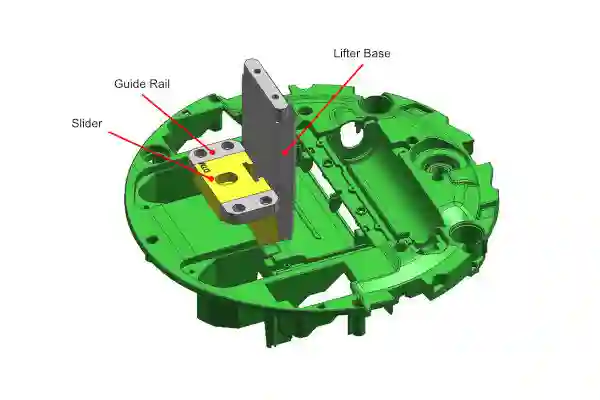

Diseño del mecanismo de extracción lateral del núcleo

- Resolución del destalonado: La socavación en el lado interior (mitad fija del molde) se resuelve mediante un mecanismo deslizante interno.

- Consideraciones sobre el diseño de las correderas:

- El pasador angular debe sellar completamente contra las fugas de plástico.

- Un borde frontal cónico en el pasador angular evita la formación de rebabas debido a la presión de inyección.

Resultados y debate

Este molde emplea una innovadora estructura de "deslizador interno de molde fijo", que ofrece un importante valor de referencia para diseños similares. Los resultados clave incluyen:

- Desmoldeo suave y movimiento mecánico fiable durante la producción a largo plazo.

- Dimensiones estables de la pieza y ensamblaje sin juntas tras el moldeo.

- Alta satisfacción del cliente gracias a una calidad constante y a la eficiencia económica.