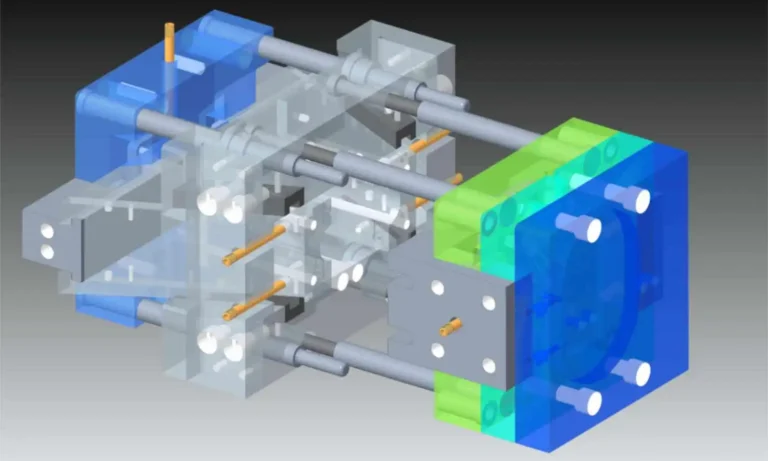

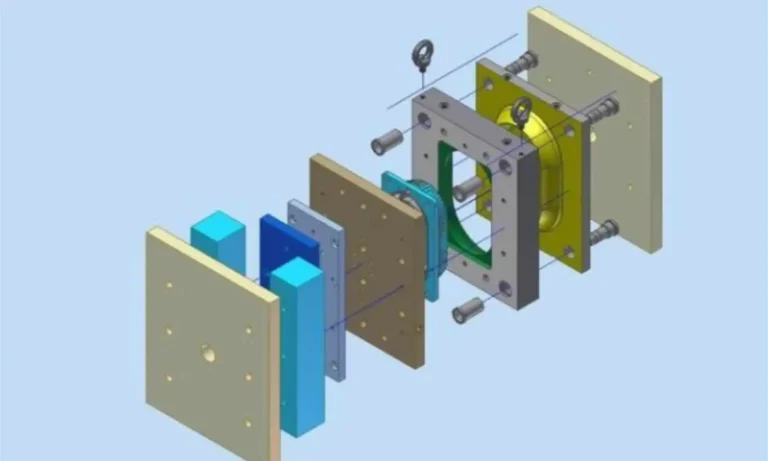

What is injection molding

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. Injection molding is a versatile and efficient manufacturing process primarily used for mass-producing plastic parts.…