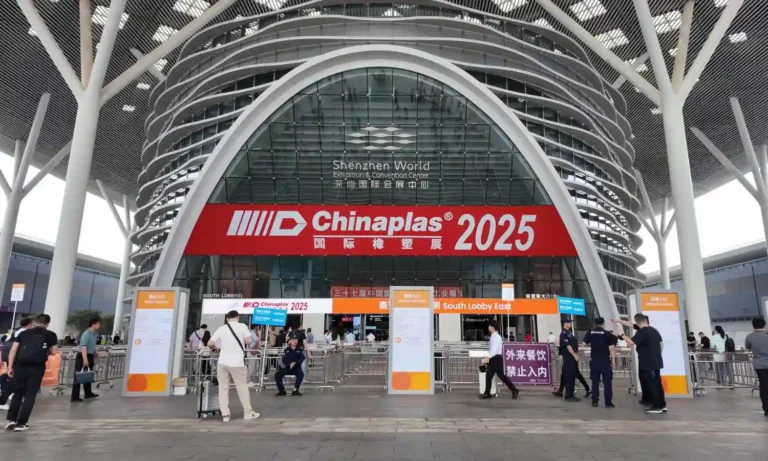

JBRplas Celebrating 30 Years of Innovation in Plastic Manufacturing

On a crisp November morning in 2025, the industrial park in Songgang, Shenzhen, buzzed with an energy that transcended the usual hum of machinery. Balloons danced in the breeze, and the scent of celebration hung in the air. JBRplas, a…