사출 성형이란?

사출 성형은 열로 녹인 플라스틱 재료를 금형에 주입한 후 냉각 및 응고시켜 성형 제품을 얻는 방법입니다. 사출 성형은 주로 플라스틱 부품 대량 생산에 사용되는 다양하고 효율적인 제조 공정입니다....

사출 성형은 열로 녹인 플라스틱 재료를 금형에 주입한 후 냉각 및 응고시켜 성형 제품을 얻는 방법입니다. 사출 성형은 주로 플라스틱 부품 대량 생산에 사용되는 다양하고 효율적인 제조 공정입니다....

방법은 다음과 같습니다: 플라스틱 제품의 가격입니다: 원재료비 + 성형가공비 + 표면처리비 + 포장비 + 운송비 + 통관비 + 관리비 = 최종 가격 사출기 비용...

사출 금형의 가격은 수천 달러에서 수십만 달러에 이르기까지 매우 다양합니다. 많은 요인이 가격에 영향을 미치며 실제로 간과하기 쉬운 "숨겨진 비용"이 몇 가지 있습니다. 두 가지를 모두 명확히 해보겠습니다...

강철 CNC 가공은 현대 제조업의 초석으로, 산업 전반의 핵심 부품에 탁월한 강도, 내구성 및 정밀도를 제공합니다. 이 가이드는 재료 선택, 가공 전략 및 후처리 기술에 대한 주요 인사이트를 종합하여 강철 CNC 프로젝트를 최적화합니다. 더 보기

사출 성형의 이해 사출 성형은 용융된 재료를 금형에 주입하여 특정 모양과 제품을 만드는 널리 활용되는 제조 공정입니다. 이 방법은 특히 플라스틱 부품 생산에 없어서는 안 될 필수 요소이지만, ...

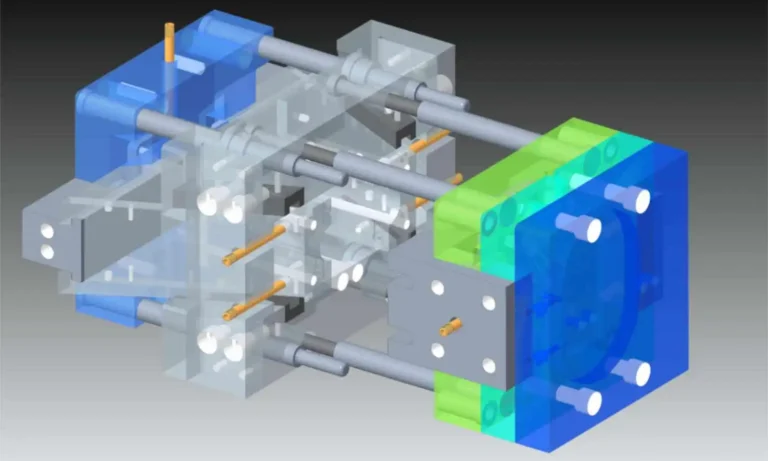

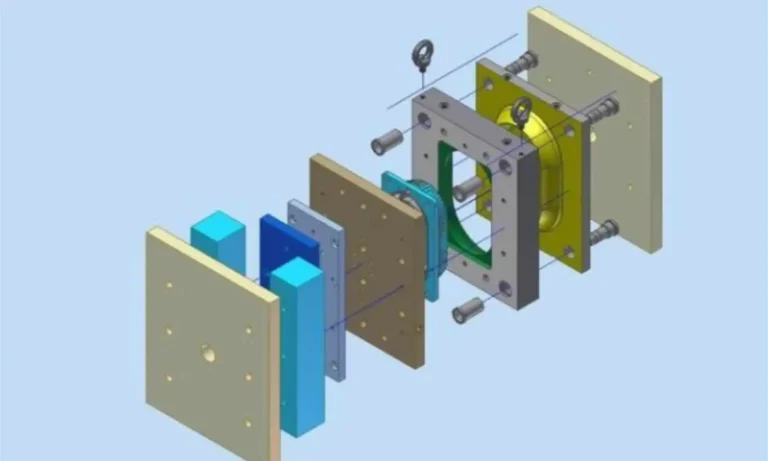

금형 설계는 자동차, 의료, 소비재 등 다양한 산업에서 정밀 부품의 대량 생산을 가능하게 하는 현대 제조의 근간입니다. 잘 설계된 금형은 제품의 일관성을 보장하고 낭비를 줄이며 생산 효율성을 최적화합니다. 이 가이드는 중요한 사항을 종합적으로 정리합니다.

이 공정은 열가소성 펠릿을 녹이고, 용융된 재료를 정밀하게 설계된 금형 캐비티에 고압으로 주입한 다음 냉각하여 원하는 모양을 만드는 것으로 시작됩니다. 주요 단계는 다음과 같습니다: 효율성은 사이클 시간 최적화, 재료 선택 및 금형에 달려 있습니다...

1995년부터 플라스틱 사출 금형 및 제조를 위한 선도적인 원스톱 솔루션 제공업체인 JBRplas에 오신 것을 환영합니다! 30년에 가까운 전문성을 바탕으로 전 세계 고객을 위한 금형 설계, 정밀 제조 및 전체 조립 서비스를 전문으로 합니다.