射出成形とは、熱で溶かしたプラスチック材料を金型に注入し、冷却固化して成形品を得る方法です。射出成形は、主にプラスチック部品の大量生産に用いられる汎用性の高い効率的な製造方法です。ここでは、その概要を構造的に説明します:

プロセスの概要

- 材料の準備:熱可塑性ペレットをホッパーに投入し、スクリューの往復するバレル内で溶融するまで加熱します。

- 注射:スクリューは、溶融したプラスチックを高圧で、しっかりと固定された特注の金型に注入します。

- 冷却:金型の中で材料が冷えて固まり、その形になります。

- 排出:金型が開き、エジェクターピンが完成品を取り出します。

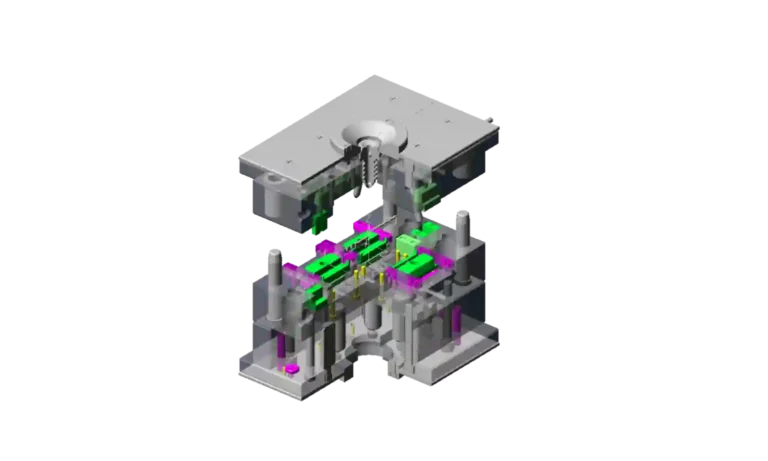

主要コンポーネント

- 機械:

- 射出ユニット:材料を溶かして注入します。

- クランプユニット:射出と冷却の間、金型を閉じた状態に保ちます。

- 金型:一般的にスチール製またはアルミ製で、キャビティ、ランナー、ゲート、冷却チャンネルを備えています。排出しやすいようにドラフトアングルが組み込まれています。

材料:

- リサイクル性と溶融性から、主に熱可塑性プラスチック(ポリエチレン、ABS、ナイロンなど)。熱硬化性樹脂やエラストマーも調整して使用できます。

アプリケーション:

- 高い繰返し精度と複雑な形状に対応できるため、自動車部品、医療機器、消費財、電子機器などの製造に広く使用されています。

メリット:

- 高効率:大量生産に適した高速生産

- 精密:一貫した複雑な部品形状。

- 素材の柔軟性:様々な素材・色に対応

制限事項:

- 高いイニシャルコスト:高価な金型設計と製作

- 設計上の制約:均一な肉厚、抜き勾配、ゲートとエジェクターピンの配慮が必要。

一般的な欠陥:

- ヒケ、ウェルドライン、ショートショット、バリなどがあり、多くの場合、不適切な温度、圧力、金型設計が原因です。

バリエーション:

- ガスアシスト成形、オーバーモールド成形、インサート成形などの技術は、用途の可能性を広げます。

環境への配慮:

- 熱可塑性プラスチックのリサイクル性とスプルー/ランナーの再利用が廃棄物を削減します。エネルギー効率の高い機械や生分解性素材は、新たなトレンドです。

まとめると、射出成形は現代の製造業の要であり、効率、精度、汎用性のバランスが取れていますが、慎重な設計と先行投資が必要です。