Lo stampaggio a iniezione è un metodo per ottenere prodotti stampati iniettando materiali plastici fusi dal calore in uno stampo, per poi raffreddarli e solidificarli. Lo stampaggio a iniezione è un processo di produzione versatile ed efficiente, utilizzato principalmente per la produzione di massa di parti in plastica. Ecco una panoramica strutturata:

Panoramica del processo:

- Preparazione del materiale: I pellet termoplastici vengono introdotti in una tramoggia e riscaldati fino a quando non sono fusi in un barile dotato di una vite alternata.

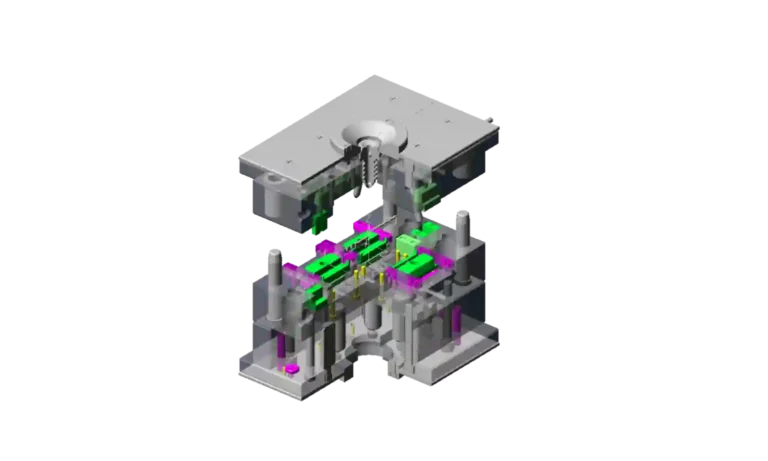

- Iniezione: La vite inietta la plastica fusa in uno stampo stretto, progettato su misura e ad alta pressione.

- Raffreddamento: Il materiale si raffredda e si solidifica all'interno dello stampo, prendendo la sua forma.

- Espulsione: Lo stampo si apre e i perni di espulsione rilasciano la parte finita.

Componenti chiave:

- Macchina:

- Unità di iniezione: Fonde e inietta il materiale.

- Unità di serraggio: Mantiene lo stampo chiuso durante l'iniezione e il raffreddamento.

- Stampo: In genere sono realizzati in acciaio o alluminio, con cavità, guide, porte e canali di raffreddamento. Gli angoli di sformo sono incorporati per facilitare l'espulsione.

Materiali:

- Principalmente termoplastici (ad esempio, polietilene, ABS, nylon) grazie alla loro riciclabilità e alle proprietà di fusione. Possono essere utilizzati anche termoindurenti ed elastomeri, con le dovute modifiche.

Applicazioni:

- Ampiamente utilizzato per la produzione di articoli come i componenti automobilistici, i dispositivi medici, i beni di consumo e l'elettronica, grazie all'elevata ripetibilità e alla capacità di realizzare forme complesse.

Vantaggi:

- Alta efficienza: Tassi di produzione rapidi, adatti a grandi volumi.

- Precisione: Geometrie dei pezzi coerenti e complesse.

- Flessibilità del materiale: Compatibile con diversi materiali e colori.

Limitazioni:

- Costi iniziali elevati: Progettazione e fabbricazione di stampi costosi.

- Vincoli del design: Richiede uno spessore uniforme della parete, angoli di sformo e un'attenta considerazione delle porte e dei perni di espulsione.

Difetti comuni:

- Include segni di affondamento, linee di saldatura, scatti corti e bagliori, spesso dovuti a temperatura, pressione o design dello stampo non corretti.

Variazioni:

- Tecniche come lo stampaggio assistito da gas, il sovrastampaggio e lo stampaggio a inserti ampliano le possibilità di applicazione.

Considerazioni ambientali:

- La riciclabilità delle termoplastiche e il riutilizzo delle materozze riducono i rifiuti. Le macchine ad alta efficienza energetica e i materiali biodegradabili sono tendenze emergenti.

In sintesi, lo stampaggio a iniezione è una pietra miliare della produzione moderna, in grado di bilanciare efficienza, precisione e versatilità, sebbene richieda un'attenta progettazione e un investimento iniziale.