1. Conoscenza di base della quotazione

(1) Dopo aver ricevuto i campioni o i disegni del cliente per la richiesta di informazioni, effettua la revisione dei disegni e la quotazione preliminare.

- Considerazioni sulla revisione dei disegni: Materiale, dimensioni, struttura, requisiti di tolleranza 2D (i costi aggiuntivi per i pezzi di ricambio, le prove multiple e le revisioni devono essere inclusi nel preventivo per i pezzi complessi o di alta precisione).

- Requisiti del cliente per il materiale dello stampo e il trattamento termico: I materiali di qualità superiore aumentano i costi.

- Complessità strutturale: Strutture più complesse (ad esempio, stampi a tre piastre, meccanismi di scorrimento, sistemi di raffreddamento) comportano costi più elevati.

- Raccomandazioni tecniche: Consigliare i clienti sull'ottimizzazione del design del prodotto per semplificare la struttura dello stampo, ridurre i costi e migliorare l'efficienza produttiva.

(2) Fattori che influenzano il prezzo dello stampo

- Durata di vita della muffa: La selezione del materiale e la progettazione strutturale hanno un impatto diretto sui costi del materiale e della lavorazione.

- Precisione del prodotto: La maggiore precisione richiede processi di lavorazione e progettazione più rigorosi, aumentando i rischi e i costi.

- Progettazione strutturale dello stampo: Dettato dalla durata, dalla precisione e dai requisiti di lavorazione, che influenzano direttamente i costi di produzione.

2. Componenti della quotazione degli stampi in plastica

- Informazioni sul prodotto: Nome, numero di parte, tipo di resina, numero di cavità, ecc.

- Costi di sviluppo del mercato.

- Costi di ingegneria:

- Gestione del progetto

- Design dello stampo

- Programmazione CNC

- Ispezione QC

- Costi dei materiali (varia a seconda del grado di stampo):

- Base dello stampo

- Inserti per nucleo/cavità

- Cursori, sollevatori

- Elettrodi (elettrodi di rame)

- Componenti acquistati:

- Sistema Runner

- Sistema di espulsione

- Sistema di raffreddamento

- Sistemi ad azione laterale e ad apertura di muffa

- Altri componenti

- Costi di lavorazione:

- Tornio, fresatura, foratura, rettifica, CNC, elettroerosione, taglio a filo, lucidatura, assemblaggio, trattamento superficiale, ecc.

- Altri costi:

- Prove + materiali

- Spedizione + dogana + imballaggio

- Consegna del campione

- Commissioni di gestione

- Termini di pagamento e programma di consegna

- Valutazione del ciclo di produzione degli stampi

3. Classificazione delle muffe per grado

Basato sugli standard SPI-SPE:

- Classe 101 Stampo (1.000K+ scatti, produzione di precisione a lungo termine):

- Materiali ad alta durezza (ad esempio, acciaio DME #2, acciaio 4140, 48-50 HRC).

- Controllo della temperatura, componenti temprati e canali dell'acqua antiruggine.

- Stampo di Classe 102 (scatti ≤1.000K, produzione di massa):

- Simile alla Classe 101, ma con caratteristiche opzionali (ad esempio, perni di guida, piastre rigide).

- Stampo di Classe 103 (≤500K scatti, produzione media):

- Acciaio P20 (28-32 HRC) o equivalente.

- Stampo di Classe 104 (≤100K scatti, produzione a basso volume):

- Basi per stampi in acciaio morbido o in alluminio.

- Stampo di Classe 105 (≤500 scatti, stampi prototipo/test):

- Alluminio, resina epossidica o materiali a basso costo.

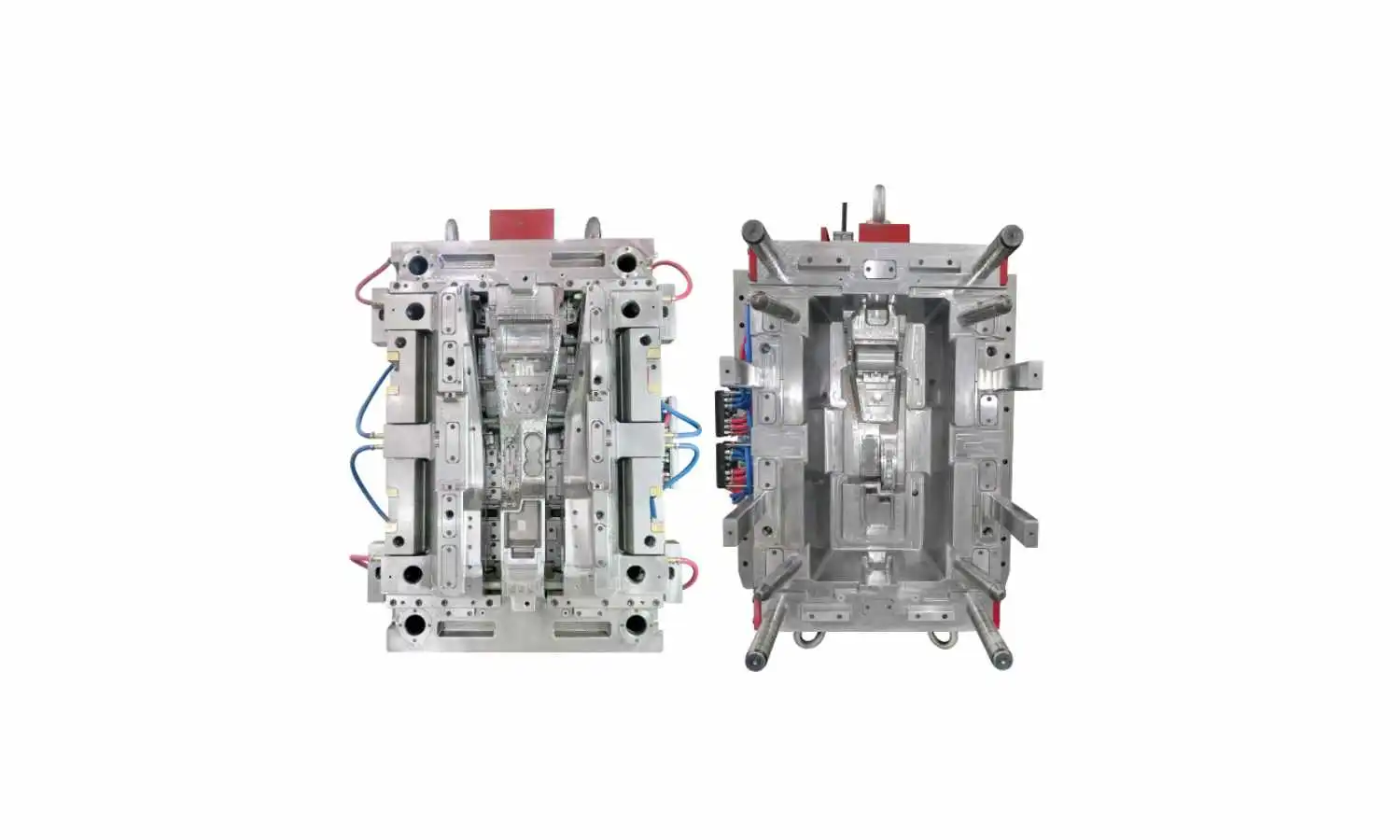

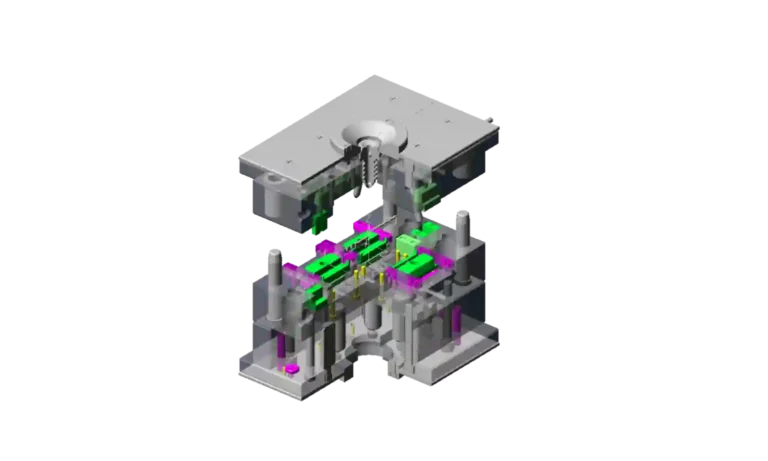

4. Struttura di base dello stampo

La struttura di base di uno stampo può essere suddivisa in sistemi funzionali: Sistema Runner, Sistema di formatura, Sistema di controllo della temperatura, Sistema di ventilazione, Sistema di espulsione, Sistema di apertura/chiusura dello stampo, Azzeramento del sistema

- Base dello stampo:

La base dello stampo funge da struttura dell'intero stampo. Tutti i componenti sono progettati in base alla struttura della base dello stampo.- Costo: In genere, il costo è pari a 10%-30% del costo totale dello stampo.

- Componenti:

- Piastra superiore (piastra di serraggio)

- Piastra A (piastra anteriore dello stampo)

- Piastra B (piastra posteriore dello stampo)

- Piastra C (pilastro di supporto)

- Piastra inferiore

- Piastra di espulsione

- Piastra di ritegno dell'espulsore

- Perni di guida, perni di ritorno, perni di espulsione, colonne di sostegno, perni di arresto, ecc.

- I principali fornitori di basi per molle:

- Cina: LKM (Long Ji Mold Base), Hongfeng, Zhonghua, Mingli.

- Internazionale: FUTABA (Giappone), DME (USA), HASCO (Germania), STRACK (Europa).

- Sistema di formatura stampi

- Inserti per anime e cavità (inserti per stampi):Incorporato nelle piastre di base dello stampo per ridurre i costi e semplificare la lavorazione.

- Requisiti del materiale: Alta durezza (28-65 HRC), resistenza alla corrosione e stabilità termica.

- Terminologia:

- Stampo anteriore (cavità/stampo madre)

- Stampo posteriore (nucleo/stampo padre)

- Cursori e sollevatori:

- Cursori: Utilizzato per formare sottosquadri o caratteristiche laterali.

- Sollevatori angolari: Assistere nell'espulsione di geometrie complesse.

- Sistema (S.R.G):

- Materozza: Collega l'ugello della macchina a iniezione allo stampo.

- Corridore: Canali che distribuiscono la plastica fusa alle cavità.

- Cancello: Punto di ingresso della plastica fusa nella cavità.

- Componenti standard dello stampo:

- Marchi nazionali: LKM (Cina).

- Marchi internazionaliDME (USA), HASCO (Germania), STRACK (Germania), EOC (Europa), STAUBLI (Francia), MISUMI (Giappone), NITTO (Giappone).

5. Classificazione degli stampi di plastica

- Per durezza del materiale:

- (1) Stampi temprati (tempra completa):

- Gli acciai per anime/cavità necessitano di un trattamento termico (ad esempio, la tempra) per ottenere 44+ HRC.

- Materiali: H11, H13, 420, S7.

- Durata di vita: 500.000+ scatti.

- (2) Stampi pre-induriti (PRE-induriti):

- Acciai per anime/cavità (ad esempio, P20, NAK80, alluminio) con <42 HRC.

- Durata di vita: <500.000 colpi.

- (1) Stampi temprati (tempra completa):

- Con la progettazione strutturale:

- (1) Stampi standard:

- Stampi a due piastre

- Stampi a tre piastre

- (2) Stampi filettati:

- Espulsione automatica della vite (motorizzata, idraulica).

- Stampi multistrato per la produzione di grandi volumi.

- Richiede sistemi a canale caldo per l'automazione.

- (3) Stampi per impilare

- Definizione: Gli stampi a pila, noti anche come "stampi a sandwich", sono costituiti da due o più strati di stampo impilati insieme.

- Caratteristiche:

- Richiede un lungo canale principale per distribuire il materiale fuso a una piastra centrale del canale caldo.

- Ideale per i pezzi piatti, a parete sottile e per la produzione di grandi volumi.

- Tre superfici di separazione devono aprirsi contemporaneamente.

- La forza di serraggio aumenta solo di 5%-10%ma la capacità produttiva raddoppia.

- Sfide:

- I sistemi a canale freddo richiedono la rimozione manuale degli scarti del canale, complicando l'automazione.

- La tecnologia dei canali caldi è fondamentale per ottenere una produzione automatizzata efficiente.

- (4) Stampi per inserti

- Stampaggio di inserti:

- I componenti pre-posizionati (ad esempio, gli inserti metallici) vengono inseriti nella cavità dello stampo prima dell'iniezione.

- La resina fusa si lega all'inserto per formare un unico prodotto integrato.

- Stampaggio Outsert:

- Un processo specializzato in cui la resina viene sovrastampata su aree localizzate di un substrato metallico preformato.

- Stampaggio di inserti:

- (1) Stampi standard:

- Classificazione per colore Quantità

- Stampi monocolore:

- Stampi a due colori:

- Combina un materiale di base duro (ad esempio, ABS, PC) con un materiale di sovrastampaggio morbido (ad esempio, TPE, TPU).

- Richiede due stampi separati:

- Prima muffa: Produce la parte di base dura.

- Secondo stampo: Posiziona la parte dura nella cavità posteriore e sovrastampa il materiale morbido.

- Considerazioni chiave:

- Allineamento preciso delle superfici di separazione.

- Complessità strutturale (cursori, sollevatori, inserti).

- Stampi multicolore (3+ colori):

- Simile agli stampi a due colori, ma con cavità aggiuntive e fasi di stampaggio sequenziali.

- Alta precisione richiesta per il posizionamento dei pezzi e l'allineamento degli stampi.

- Stampi in silicone

- Stampi in silicone solido: Per le parti in gomma.

- Stampi LSR (gomma siliconica liquida): Per l'iniezione di silicone liquido di alta precisione.